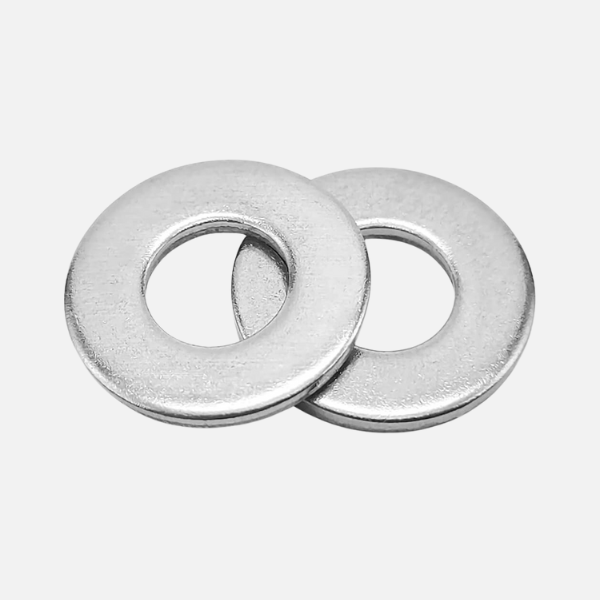

Carbon Steel Flat Washer – A High-Strength Load Distribution Washer for Construction, Machinery, and Structural Fastening | Heavy-Duty Washers in UAE

Carbon Steel Flat Washer is a significant fastening accessory designed to impart load evenly, protect assembly surfaces, and enhance joint integrity in bolted joints. These flat washers made in carbon steel are sturdy enough to withstand high-load applications in construction, industrial machinery, fabrication, and MEP installations.

By resisting damage to either surface of assembly from the compressive stress of the fastener while simultaneously restraining vibrational loosening, they confer longer fatigue life on fastened joints. Carbon steel flat washer treatment from Al Hafoof, having multiple coatings and standards, suits the most demanding situations across Dubai, Sharjah, Abu Dhabi, Ajman, and the whole GCC region.

✅ Key Features:

-

Heavy-duty carbon steel-made

Made of high-tensile-strength carbon steel (AISI 1010/1045), which makes it strong, tough, and mechanically durable under extreme pressure. -

Distribution of load evenly

Prevents bolt embedment and damage to the fastened surface, hence the most appropriate for steel structures, concrete anchors, and industrial base plates. -

Available in multiple coatings

Choose zinc plated, hot-dip galvanized, black oxide, or plain finish according to your corrosion protection requirement. -

Compatible with All Standard Fasteners

Works seamlessly with hex bolts, anchor bolts, threaded rods, and machine screws in metric and imperial sizes. -

Precisely Machined

With consistent inner and outer diameters, tight fit promotes stability and easy on-site installation.

📐 Technical Specifications:

-

Material: Carbon Steel – AISI 1010, 1035, 1045

-

Outer Diameter: As per DIN 125 / ISO 7089 / ANSI B18.22.1

-

Thickness: 1mm to 6mm (depending on size)

-

Size Range: M3 to M56 / ¹/₈” to 2”

- Standard Compliance: DIN 125 / IS 2016 / ASTM F844

Custom dimensions & packing available for industrial supply

🛠️ General Applicability:

-

Structural steel joints and base plate mounting

-

Concrete installation anchor bolt fastening

-

Heavy equipment and industrial machinery

-

MEP systems, HVAC units, and power plants

-

Automotive and transport assemblies

-

Fabrication and welding setups

-

Precast concrete and civil engineering infrastructure

These washers are engineered to prevent fastener pull-through, absorb shock, and provide stability in high-stress assemblies.

🌍 Widely Supplied Across UAE & GCC

We at Al Hafoof are one of the most reliable suppliers of Carbon Steel Flat Washers across the UAE, supplying fabricators, contractors, OEMs, and hardware distributors across Dubai, Sharjah, Abu Dhabi, Ajman, Ras Al Khaimah, and the whole Gulf region.

📈 Why Al Hafoof?

-

Consistent quality – hardness & tolerance tested

-

Very large ready stock of all common sizes

-

B2B specific custom bulk packing

-

Urgent site dispatch within the UAE

-

Trusted by leading EPCs, steel fabricators, and construction firms

📞 Order Now or Get a Quote

Need Carbon Steel Flat Washers for your project, plant, or hardware stock?

Contact Al Hafoof now for bulk pricing, technical specs, or urgent dispatch across the Emirates.

Al Hafoof – Your Trustworthy Source for Industrial Fasteners, Washers, and High-Performance Hardware in UAE & GCC.