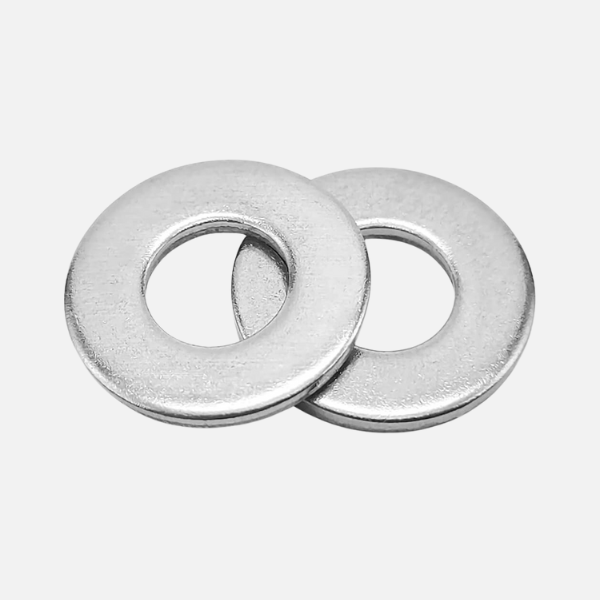

Stainless Steel Flat Washer – High-Corrosion Resistance Load Distribution Washer for Construction, Marine & Machinery Applications

The flat washer made of stainless steel is a high-quality multipurpose washer which distributes the load applied by bolted, screwed, or nut fasteners, thereby preventing surface damage and minimizing vibration and improving the strength of the joint. It is critical in all industrial, marine, structural, or mechanical applications.

SS 304 or SS 316 stainless steel of anti-corrosive nature makes this washer perform very well in damp, salty, and aggressive chemical surrounding; hence, it is suitable for outdoor, coastal, and industrial applications in the UAE and Gulf region.

✅ Primary Features Include:

🔩 Maximum Load Distribution

Surface deformations caused by pull-out resistance are prevented, increasing joint stability under the bolt head and nut contact.

🛡️ Superior Stainless Steel Material

AISI stainless steel 304 for general use and 316 for marine-grade or chloride-resistant applications, ensuring optimum protection against corrosion as well as mechanical strength.

🌊 Non-Corrosive & Rust-Free

Ideal for corrosive and wet environments, as well as high-temperature areas such as piping, marine equipment, food-grade systems, and solar structures.

🧽 Smooth and Burr-Free Surface Finish

Provides proper fitting with bolts, preventing the assembly surfaces from being scratched or scored.

⚙️ High Strength

Withstands high torque, load-bearing stresses, and temperature changes without deformation or failure.

📐 Technical Specifications:

-

Material: Stainless Steel – AISI 304 / 316

-

Size Range: M3 to M56 (Larger sizes on request)

-

Outer Diameter: Standard & Large OD (DIN 125 / DIN 9021)

-

Thickness: 0.8mm to 6mm

-

Finish: Natural / Pickled / Electropolished

-

Standards: DIN 125 / ISO 7089 / IS 2016 / ASTM A240

-

Edge Options: Chamfered or Flat

(Custom OD, slotting, and bulk packaging available for industrial clients)

🛠️ Applications:

-

Structural Steel & Base Plates

-

Marine & Coastal Infrastructure

-

Oil & Gas Platforms & Piping Systems

-

Food Processing Equipment & Hygienic Installations

-

HVAC, Pumps & Water Treatment Plants

-

Precast Concrete Anchoring Systems

-

Electrical Panels, Solar Mounts & Cable Tray Fastening

-

MEP Installations & Construction Fabrication

Perfect for any application exposed to high vibrations, corrosion, or outdoor environments, requiring long-term fastening reliability.

🌍 Supplied Throughout UAE & GCC

Al Hafoof is a renowned supplier of stainless steel flat washers to MEP contractors, infrastructure developers, OEMs, panel builders, and heavy equipment manufacturers in Dubai, Sharjah, Abu Dhabi, Ajman, and exported throughout Saudi Arabia, Oman, Qatar, and Bahrain.

📈 Why Al Hafoof?

-

✅ 100% verified stainless steel with test reports

-

✅ Bulk & ready stock for quick UAE dispatch

-

✅ Custom dimensions and large OD options

-

✅ Competitive pricing for project quantities

-

✅ Trusted partner to industrial & marine sectors

📞 Call Us Today

In search of corrosion-resistant and heavy-duty stainless steel flat washers for your project or plant?

Get in touch with Al Hafoof for the best pricing, technical datasheets, and speedy delivery throughout UAE & GCC.

Al Hafoof – Supplying High-Performance Stainless Fasteners for the Most Challenging Conditions in the Middle East.