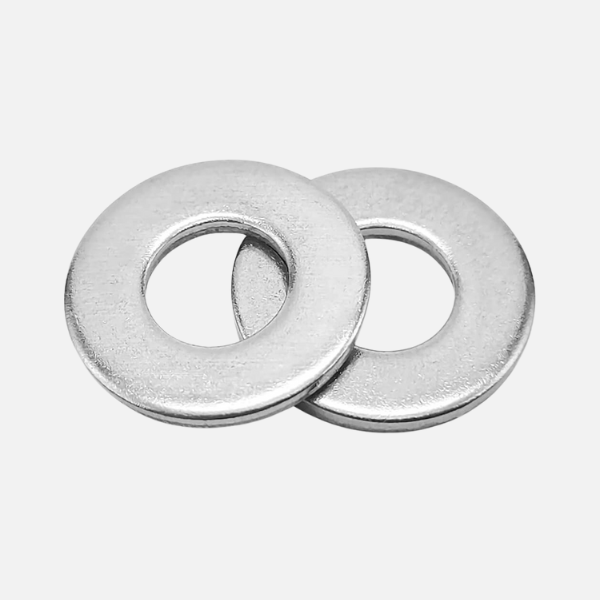

Stainless Steel Spring Washer – Anti-Loosen and Rust-Proof Split Lock Washers for Applications with Heavy Vibrations | SS 304 and SS 316 Lock Washers in UAE

This spring-type washer is called Stainless Steel Spring Washer, and it is manufactured into a split helical, used to hold tension and prevent bolt loosening as vibration occurs within mechanical assemblies. It could be said to be the most needed fastening component for high-vibration environments, such as automotive systems, industrial machinery, electrical panels, HVAC equipment, and marine applications.

This particular washer combines the properties of rust resistance, tensile strength, and long-lasting locking effectiveness—even in adverse outdoor or chemical conditions—because of the use of high-grade SS 304 or marine-grade SS 316 stainless steel.

Al Hafoof’s stainless spring washers provide the best safe, maintenance-free fastening options in critical load-bearing applications across the UAE and the GCC.

✅ Key Features:

-

Split Helical Design for Locking Grip

The twisted ring generates a spring force against the fastener preventing nuts and bolts from loosening under dynamic loads or vibration. -

Corrosion-Resistant Stainless Steel

Built from SS 304 (general industrial) or SS 316 (chloride/saltwater resistant) steel to ensure durability and rust-free performance in outdoor or marine environments. -

Ideal for Vibration-Intensive Applications

Perfectly suited for pumps, compressors, motors, railway tracks, and engine mounts where standard washers fail under stress. -

Recoil Force Maintains Bolt Tension

Keeps bolts tight even under temperature fluctuation, shock loads, or movement. -

Reusable, Clean, and Aesthetic Finish

Non-staining and polished finish makes it ideal for visible connections or hygienic environments.

📐 Technical Specifications:

-

Material: SS 304 / SS 316

-

Size Range: M3 to M48

-

Standard: DIN 127 / IS 3063 / ISO 8752

-

Finish Options: Bright Annealed / Pickled / Electro-Polished

-

Hardness: ~200 HV (SS 304), ~220 HV (SS 316)

-

Packaging: Industrial bulk packs / Custom label options

Custom dimensions, special hardness grades, and large OD variants available on order

🛠️ Common Applications:

-

Mechanical Equipment & Industrial Motors

-

Marine & Offshore Installations

-

Railways, Cranes & Heavy Machinery

-

Solar Mounting Structures & Outdoor Equipment

-

Automotive Assemblies & Engine Fasteners

-

Electrical Control Panels & Distribution Boards

-

Plumbing, MEP, and HVAC Systems

-

Steel Frame Fastening & Fabrication Projects

This washer is a must-have for dynamic assemblies, where nuts and bolts are constantly being put under stress, heat cycles, or vibration.

🌍 Widely Supplied Across UAE & GCC

Al Hafoof is a foremost supplier of Stainless Steel Spring Lock Washers in Dubai, Sharjah, Abu Dhabi, Ajman, Ras Al Khaimah, and throughout the Middle East. OEMs, electrical contractors, industrial fabricators, HVAC integrators, and hardware wholesalers trust operations throughout this area with Al Hafoof quality products.

📈 Why Al Hafoof?

-

100% SS 304/316 with Material Test Certification

-

Precision Machined to Global Standards (DIN/ISO)

-

Available for Bulk Stock Urgent Project Needs

-

Fast Delivery in the UAE with Export-Grade Packing

-

OEM and Custom-sized Tightening Solutions Supported by Technical Guidance

📞 Order Now – Stainless Steel Spring Washers That Lock and Last

Need Stainless Steel Spring Washers that lock and last, resisting corrosion?

Talk to Al Hafoof today for bulk price, size advice, or custom specs for your industrial or marine-grade needs.

Al Hafoof – The Trusted Source of the UAE for Stainless Fasteners and Locking Washers That Never Back Off.